NOTE *This article was originally published January 2017 for Foundations Revealed. The link can be found here.

In part 1 I worked with a pattern developed from ‘The Athletic Corset’ as featured in ‘A practical guide to corset cutting and making’ by William D.F. Vincent.

Now I’ll go on to create my own corset.

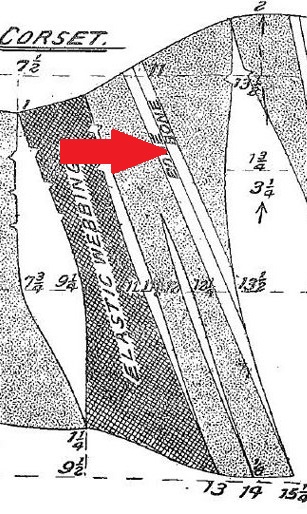

Given both its likely date and its function-over-fashion design, this corset could have been constructed using a single layer of coutil, keeping it lightweight but durable for wear during sporting activities. For this reason I chose a black broche (a heavyweight coutil with a subtle dot pattern) and a strong powernet (in place of the elastic webbing)

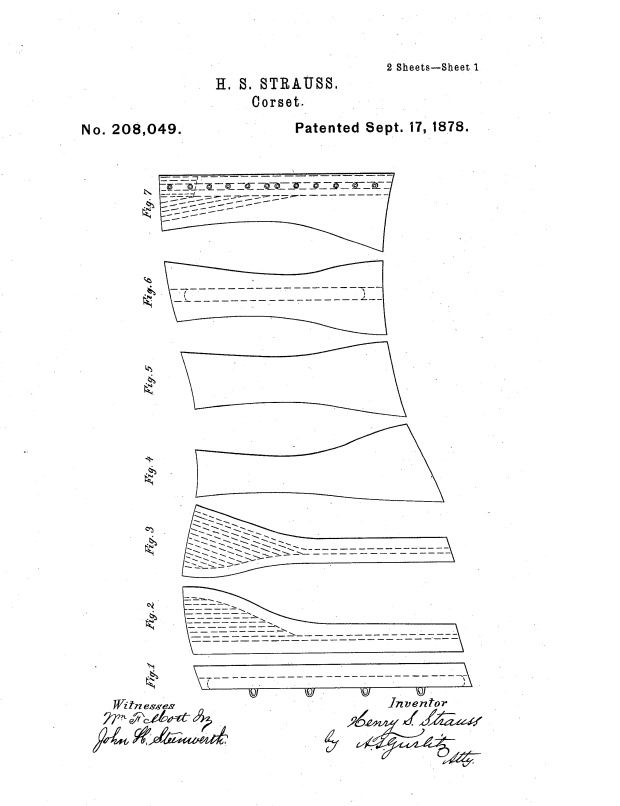

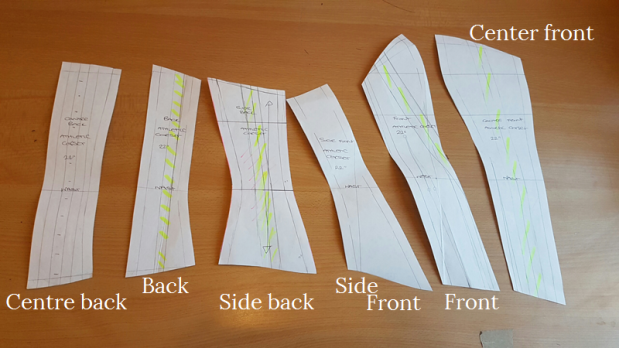

The corset was cut as follows:

- 2 layers of broche to sandwich the busk: CUT 2 PAIRS CENTRE FRONT

- 2 layers of broche for centre back eyelet panel: CUT 2 PAIRS CENTRE BACK

- Single layer of broche for the rest of the plain pieces: CUT 1 PAIR FRONT, SIDE BACK, BACK

- Single layer of powernet used in place of the woven elastic panels: CUT 1 PAIR SIDE FRONT

Preparing the Boning Channels

I decided to sew the corset seams wrong sides together, using external bone casings to cover the seam allowances. The pattern also indicated the placement of additional exterior channels, most of them down the centres of the panels.

I began with 27mm wide strips of broche, cut parallel to the selvedge, and used a 12mm bias tape maker to create single bone casings for the channels covering the seams.

For the other channels I wanted double bone casings, so I cut those channels 52mm wide and used a 25mm tape maker for those. When applying them, I stitched close to the edge either side, and then added the dividing line of stitching down the centre to create the twin channel.

Inserting the busk

The pattern used a simple flat steel busk. The two CENTRE FRONT pieces were placed right sides together and stitched in order to insert the busk in the usual way.

Preparing the FRONT panel

Following the marking on the pattern, the shaped dart in the FRONT panel was stitched closed before joining to either the centre front or side front pieces.

A double bone channel was also needed on this panel. This will be the only one applied before the main construction, since it seems to disappear into the FRONT/CENTRE FRONT seam.

The angled placing made positioning tricky as I tried to make the sides symmetrical. I was concerned about whether making the channel end in the seam would create awkward bulk, and whether I would be able to stitch down another channel to overlap the seam.

Assembling the front section

I stitched the FRONT/CENTRE FRONT seams wrong sides together, and then the FRONT/SIDE FRONT seams in the same way. This was the seam where the broche met the powernet, so I used a secure stitch on either end of the seam to control the powernet whilst stitching, and stop it from slipping.

CENTER BACK panel: Boning channels

I created the centre back edge by stitching CENTER BACK broche sections right sides together, then turning to the right side and pressing. I used the side of my sewing machine foot as a guide to create three equal channels for the eyelets and flat steels.

Assembling the back section

I stitched the BACK/CENTRE BACK seams wrong sides together, and then the BACK/SIDE BACK seams in the same way.

Joining front and back sections and applying bone casings

The front and back sections were joined wrong sides together. Again, secure stitches were used on each end to help control the powernet.

Applying the bone casings

I trimmed the seam allowances and pressed them down. (I turned the seam allowances in the powernet back onto the broche reasoning that stitching the boning casings onto the power net might cause the seam to crack under pressure). Then I applied the single bone casings over them, on the outside of the corset.

Then I applied the wider double bone channels to the centre front panel and side back panel. I should have used a double channel for the back according to hte pattern, but I found that the panel wasn’t wide enough, so a single casing had to make do instead.

Boning

I used spiral steel boning throughout most of the corset, with flat steels either side of the eyelet channel in the centre back.

Binding

I wanted to use the broche for binding, but found that it would cause difficulty when sewing, especially at the ends. Instead I chose a satin finish pre-folded bias binding. I first machine stitched it to the right side and then flipped it over and top stitched in place.

Eyelets

Finally I inserted twelve pairs of eyelets, as marked on the pattern.

The Finished Corset

I was pleased with the finished corset. I love the textural contrast of the mesh to the broche fabric. My choice of a sheer mesh allows the undergarment or skin to show through, adding interest to an otherwise fairly plain design.

Having worn and tested the corset with lots of bending and stretching, I felt that it was supportive, yet the stretch mesh panel provided me with some freedom of movement. The corset could be laced closed, reducing the waist but not being too restrictive.

I was pleased with the cut of the corset around the cup shape and under the arm. It was cut low, allowing full movement of the arm, yet still had good coverage of the breasts. The pattern could easily be adapted for use as a fashion corset.

The corset is cut short at the back, allowing the wearer to bend and sit comfortably.

I liked the idea of the double bone casing, providing both additional support and an eye-catching feature. A contrast colour could be used to make them stand out.

I would probably remove the dart from the pattern for future use, and instead take the fullness out of the front panels from the sides. It could be tapered a little more at the centre front/front seam, bringing the corset closer to the body.

Vincent’s Athletic Corset does perform as advertised. It’s a comfortable, everyday corset, providing control and shape for the wearer whilst allowing considerable freedom of movement.

This sample is available to buy from my ETSY store.